The Truth about The Shymkent Refinery. Part 1

Photo: petrosynthesis

Photo: petrosynthesis

The oil industry experienced a memorable summer. All three refineries stopped working at the same time. Pavlodar needed repairs, a part failed at Shymkent, and Atyrau stopped working due to an accident at the MAEK. As a result, there is a risk of a shortage of all types of fuel and an increase in prices. But it seems like the situation has improved, the public has calmed down, and two of the three refineries have been relaunched. Yet this is all with one big "but". A failed part is not a force majeure situation as it has been presented to citizens and the government. The fact that it would fail was known more than six months ago. Orda looked into the situation.

The Shymkent refinery was put into operation in the 80s. In September 2018, PetroKazakhstan Oil Products (PKOP LLP), which owns the company, completed the final stage of modernization. Some of the units had been adapted to a lower capacity and processing of high-paraffin Kumkol oil and high-sulfur Aqtobe oil.

The aim of the modernization was to restore the capacity for primary oil refining to 6 million tons per year and increase the depth of processing and yield of light oil products. And also bringing the quality of motor fuels to the requirements of the Customs Union's technical regulations.

According to data for 2022, the plant supplies:

- 60% of Kumkol oil.

- 20% of oil from the fields of Western Kazakhstan.

- 20% of oil from the fields of the Aqtobe region.

The Equipment Served Its Purpose

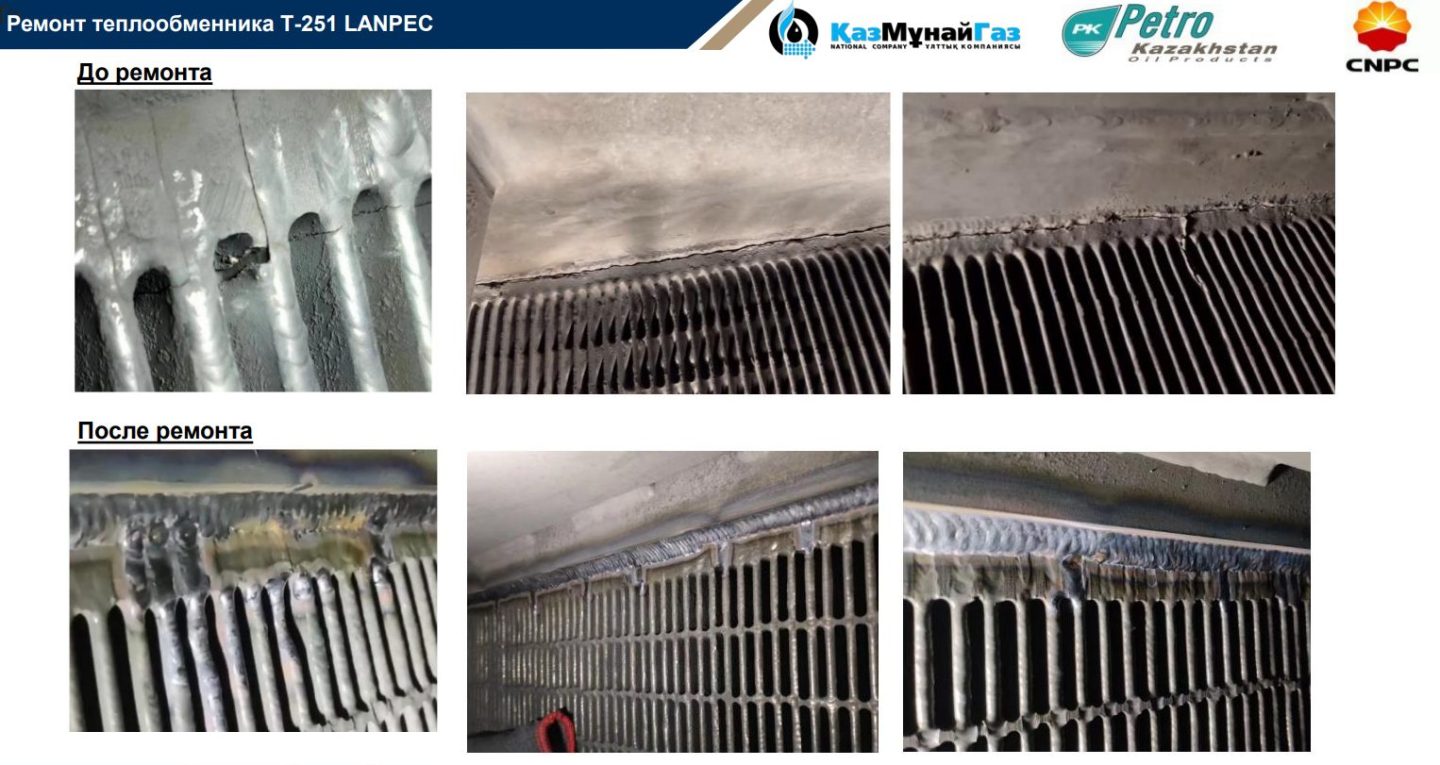

From March 15 to April 7, the Shymkent Refinery carried out scheduled preventive maintenance (SPM). In early July, the T-251 catalytic reforming heat exchanger failed at the Shymkent refinery. Replacement would have cost the plant at least $10 million.

At the same time, instead of buying a new part, they just decided to repair it. However, as an Orda correspondent has learned, they had known about the need to replace the heat exchanger last year. But for some reason, the owners of the refinery did not include its cost in the budget. They did not want to change it during the scheduled preventive maintenance, which ended on April 7. Yet in the acts, the contractors indicated that the part would not last long.

The T-251 heat exchanger was put into operation back in 2010. According to the report on the current activities of PetroKazakhstan Oil Products LLP, in June 2023, a leak was detected for the first time in February. On March 20, PKOP brought in specialists from the LANPEC manufacturing plant to repair it. A chief engineer, a mechanical engineer and a welder came from China. They discovered cracks in the seams in the high-temperature zone.

After the repair, the residual leakage between the cavities was no more than 1%. The report indicated that this corresponded to the loss of the octane number. But it was this 1% that began to influence the number of additives for the production of AI-95. According to LANPEC experts, the heat exchanger would be able to work for no more than a year under favorable operating conditions. I.e. the absence of sharp fluctuations in temperature and pressure. But every summer in Shymkent there are heat, pressure, and strong temperature fluctuations.

PKOP LLP took into account the recommendations and concluded an agreement: the part should be delivered within 8 months – in January 2024.

The broken heat exchanger is already 13 years old, they talked about replacing it last year, but they put everything on hold, pretending that what happened at the Shymkent refinery was just an unforeseen circumstance and not a concealment of information.

When the part failed, the representatives of the plant asked another company to repair it. PKOP sent the corresponding document on June 15 but did not receive a response from AVC Production. On the same day, a document was distributed for internal use that due to a broken heat exchanger, the refinery would reduce the output capacity of AI-95 gasoline.

Meanwhile, PKOP LLP assured KazMunayGas that Chinese LANPEC welders would arrive in early July. They had to get permission to leave the country from the PRC. So why were repairmen from Kazakhstan needed if Chinese specialists sort of looked at the heat exchanger for the second time in a year? Or were there welders, but the part failed after only a few days?

An Employee's Perspective: There Were Problems with The Production of AI-95 Gasoline Already in May

As the source at the Shymkent refinery told Orda, the quality of operation at the plant has dropped significantly over the past 1-1.5 years.

"On March 15, major repairs began, 10 days before completion (April 7-8 – Ed.), the reforming contractor reminded about a leak of 1% on the T-251 heat exchanger. And I also mentioned LANPEC representatives who were at the plant on March 20-22. They reminded that this is not their area of responsibility and announced that it is necessary to call people who will be able to weld the seams. At the same time, there is an oddity: LANPEC representatives were at the plant in March, and their welders – only in early July. Sabotage by the PCOP? No, there's a hidden business there."

According to the source, the Chinese side proposed to delay the overhaul for 10-12 days. And during this time, solve the issue with the failing part. But Kazakhstani businessmen assured that they have the relevant experience. The asset would work for a year, despite the 1% leak. Already in May, the heat exchanger began to fail again.

"The Chinese also began to operate the refinery poorly, having given their trust to Kazakh businessmen. Prior to that, the catalyst activity was planted and they were bought up for regeneration. Thus, they hid their mistakes about the low quality of operation. Even the need for a new heat exchanger was known before the overhaul in January-February 2023, it took a long time to decide through which company to order. At the end of March, we decided first to pre-launch, and then to start the plant and also signed the acts. And after three weeks, the seam began to spread. In mid-May, it was already too late to produce AI-95 with a high involvement of additives."

Plant's Technical Supervision and Mechanics Blamed in The Report

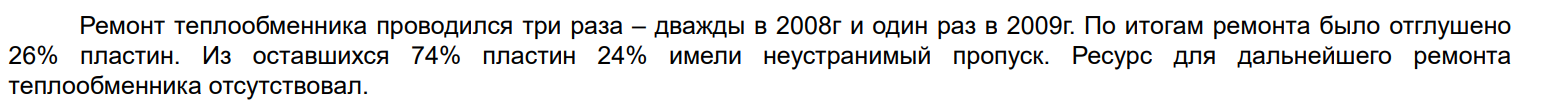

If the catalytic reforming heat exchanger turned 13 years old this year, then the plastic T-250 is 23 years old. It was replaced by a group of direct-flow parts in 2000.

In 2008 and 2009, three repairs were carried out. As a result, 26% of the plates were turned off. Of the remaining plates, 24% of the defect could no longer be eliminated. In 2010, instead of the T-250, a new part was installed – the T-251. And they decided to use the old one to regenerate the gasoline reforming unit.

On June 8, 2023, specialists of AVC Production LLP arrived at the plant, who are involved in the ANPZ's repair. After examining the heat exchanger, they reported that it was impractical to repair it on the spot. This would only "worsen the mechanical integrity and reliability of operation." The part had to be dismantled and transported to France, where it was manufactured.

"The T-250 has been out of order for a long time, this lesson should have been learned by the technical director of PKOP Bakhyt Yeregenov. But when they were preparing to close the reforming and were preparing the plant for pre-commissioning, they were reminded about the T-251 that its 1% seams leak. And then there was an accident, in "PKOP" they began to write to KMG, as if the part had broken due to force majeure, hiding the background. At the same time, an investigation is underway in parallel on the failure of the heat exchanger, meanwhile PKOP LLP is preparing a report. They want to conceal the meeting of top managers. The report will indicate that the technical supervision and mechanics of the plant are to blame for everything. But in April, when the plant was launched, they told technical director Yeregenov that they did not want to sign acts,"

a source at the refinery said.

As told to an Orda correspondent, many PKOP LLP employees have little experience in this field. The main specialists left, leaving the "students" in their place. This will be covered in detail in the second part.

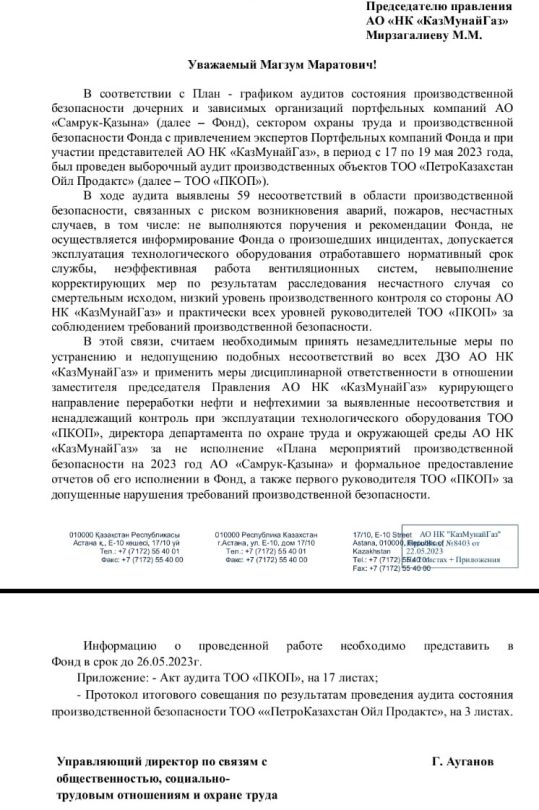

59 Comments from Samruk-Kazyna

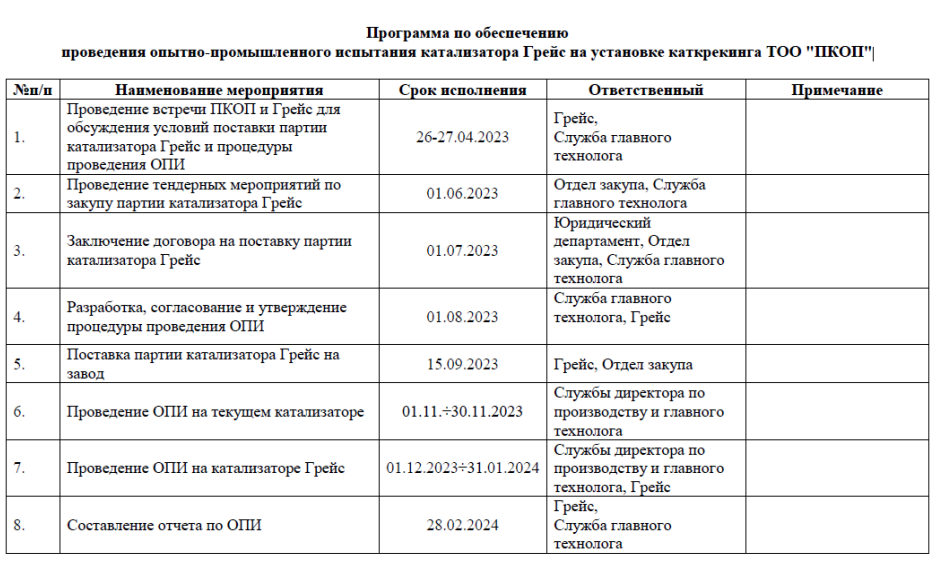

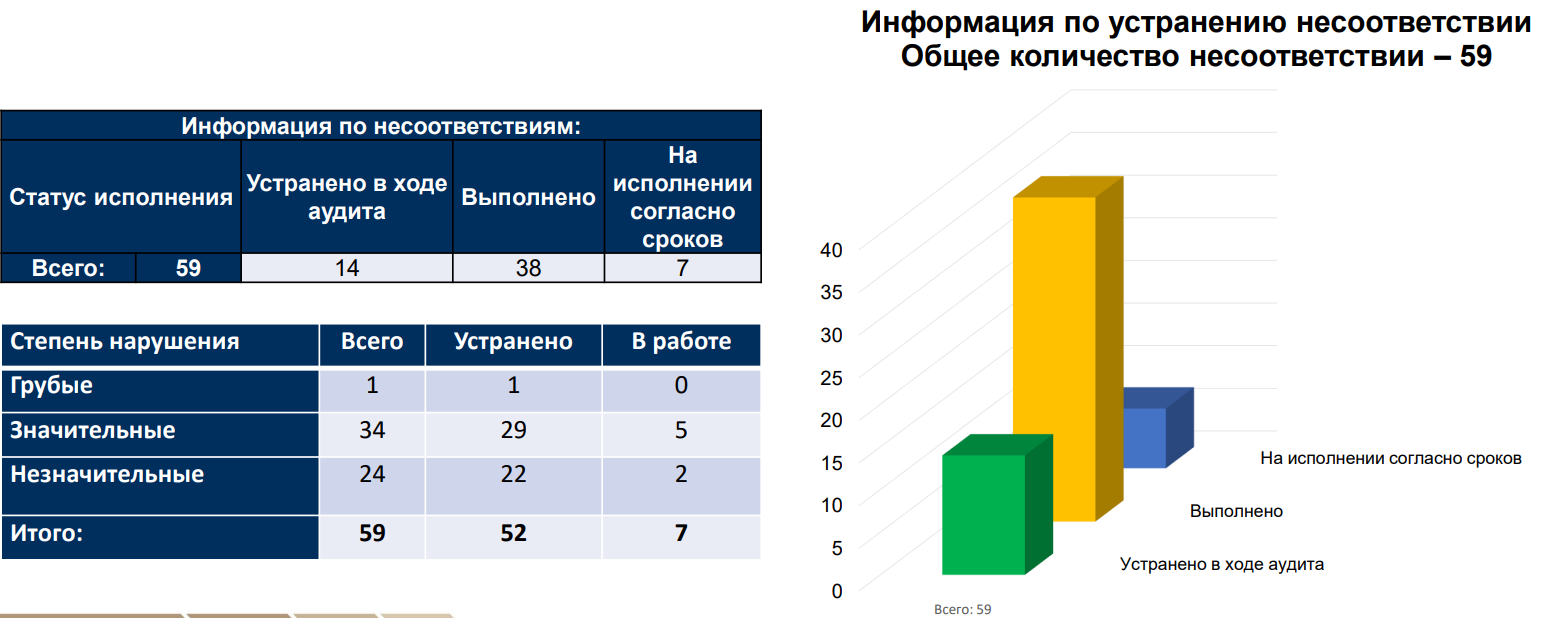

From May 17 to May 19, 2023, the Samruk-Kazyna Group conducted an audit at the Shymkent refinery. Employees checked the state of industrial safety of subsidiaries and dependent organizations and portfolio companies of the national holding.

As a result, in just three days, the auditors identified 59 concerns. 14 of them were eliminated on the spot. The remaining ones were approved in the "Action Plan to eliminate the identified inconsistencies", which was signed on May 25. The order also appointed people responsible for the execution. The audit is 17 sheets. Already on May 26, the foundation was waiting for information about the work carried out.

The revealed violations were followed by disciplinary responsibility. KazMunayGas asked the President of CNPC, Bian Dyzhy, to consider bringing the president of PKOP LLP, Yerbolat Kozhabayev, to disciplinary responsibility. They had to decide whether to involve him or not at an extraordinary general meeting of the stakeholders (founders).

By July 10, 39 violations had been corrected at the Shymkent refinery. They had promised to solve everything on time regarding the remaining 7 points.

Screenshot of the report on the current activities of PetroKazakhstan Oil Products LLP for June 2023

Small Salary and Alterations for Contractors

As Nurlan Zhumagulov, director of the Energy Monitor Public Fund, was told by Shymkent refinery's employees, they are tired of finishing work after contractors and at the same time receiving low wages.

"Work has been completed on the reforming unit with the launch, but to date (July 14, 21:15 – Ed.), AI-95 gasoline is not being produced. Octane is not catching up, and using more additives is detrimental to the economy of the plant. The processors are not happy with the fact that they pay for processing according to the tariff, but they do not receive the required amount of gasoline, diesel, jet fuel and gas according to the documents. Most likely, this heat exchanger could not be repaired, they just partially dulled the plates, reducing the efficiency. The catalyst will not help fix the gasoline quality problem. Hydrogen production has not been restored: this affects the output of diesel. The discontent of small proccessors is justified,"

Zhumagulov wrote.

Nurlan Zhumagulov proposed to give the management of the plant to Chinese investors, as they own 51% of the participation share. Perhaps, in this case, the issue with the transportation of MMA octane-boosting additives would be solved much faster. Now it is purchased through intermediaries.

Until 2021, the Shymkent Refinery was the most reliable plant with low tariffs and high quality of operation. What happened to the heat exchanger cannot be called a force majeure and the regeneration of the catalyst is an unscheduled stop. The management knew that the part barely worked, but they decided to stall for time and hoped for luck.

In the next part of the Orda.kz will tell you about the insurance of employees and the reconstruction of the diesel plant, which was started back in 2011.

Original Author: Maria Gorbokonenko

DISCLAIMER: This is a translated piece. The text has been modified, the content is the same. Please refer to the original article in Russian for accuracy.

Latest news

- President Toqayev Sends Nazarbayev Birthday Wishes

- Toqayev Appoints New Ambassadors in Series of Diplomatic Changes

- Unidentified Object Resembling Drone Found in Atyrau Region

- Trump and Zelenskyy Discuss Air Defense Needs

- Rapper Qurt: Wife Withdraws Statement in Court

- Head of Azerbaijani Cultural Autonomy in Moscow Region Reportedly Loses Russian Citizenship

- Defense Secretary Hegseth Paused Ukraine Weapons Shipment Despite Pentagon Assessment — NBC

- Prosecutor General's Office Confirms Detention of Kozhamzharov's Associate in Torture Case

- State to Scale Back Role in Competitive Sectors

- Uzbek Banker Kidnapped in Paris

- Former Financial Police Officials Reportedly Detained, Case Concerns Torture

- Progress MS-31 Launches from Baikonur Carrying Fuel, Water, and Scientific Cargo

- Two Men to Face Trial for Homicide of Missing Atyrau Woman, Body Not Found

- Russia Launched Massive Strike on Ukraine Following Trump–Putin Call

- Rapper Qurt Accused of Abuse by Wife

- Pavlodar Region: Rescuers Seek Lower Retirement Age Amid Strain of Risky Work

- Businessman Vagif Suleymanov Detained in Moscow

- Kashagan Field Reaches One Billion Barrels of Oil Extracted

- Lenin Street in Osh Renamed After 19th-Century Kyrgyz Leader

- New Uranium Plant Launched in Turkistan Region with French Partnership