“It Was Impossible to Mix Up the De-Icing Fluids!” — Witnesses in the 2019 Plane Crash Case

Photo: Orda.kz

Photo: Orda.kz

The Turksib District Court of Almaty continues to hear the high-profile case of the crash of a Bek Air airliner in December 2019, Orda.kz reports.

Investigators say the culprits are the deceased aircraft commander, Marat Muratbayev, and co-pilot Mirzhan Muldakulov. They say the pilots tried to save on anti-icing by instructing airport technical staff to remove snow and ice only from the tail unit. The wings were not cleaned, which is why the Fokker 100 failed to gain altitude, crashed, and struck a private house.

Twelve people were killed, and 69 were injured.

Several witnesses spoke in defense of the deceased pilots. The former head of Bek Air stated that airport ground staff had mixed up containers with de-icing liquid, using a weaker solution instead of the concentrated one.

The former chair of the flight subcommittee believed that technicians had incorrectly removed snow deposits from the stabilizer.

Witnesses from among the airport’s engineering and technical staff, heard online, said they acted strictly according to instructions. They said they could not have mixed up the liquids or improperly prepared the plane for takeoff, since they carried out their duties responsibly.

To complete the picture, the court also heard testimony from the crews of other aircraft to determine how they performed de-icing procedures in 2019. These crews managed to take off safely and reach their destinations that same morning.

Error Excluded

The first to speak via video link was Maxim Shulyak, an engineer for servicing special equipment at Almaty International Airport. He warned the court that he had not personally seen his subordinates removing ice from the stabilizer of the Fokker 100 on the morning of December 27, 2019, because his working day began later.

He therefore spoke in general about the storage conditions of de-icing fluid, quality control, and the regulations for the driver and operator of a special deicer vehicle.

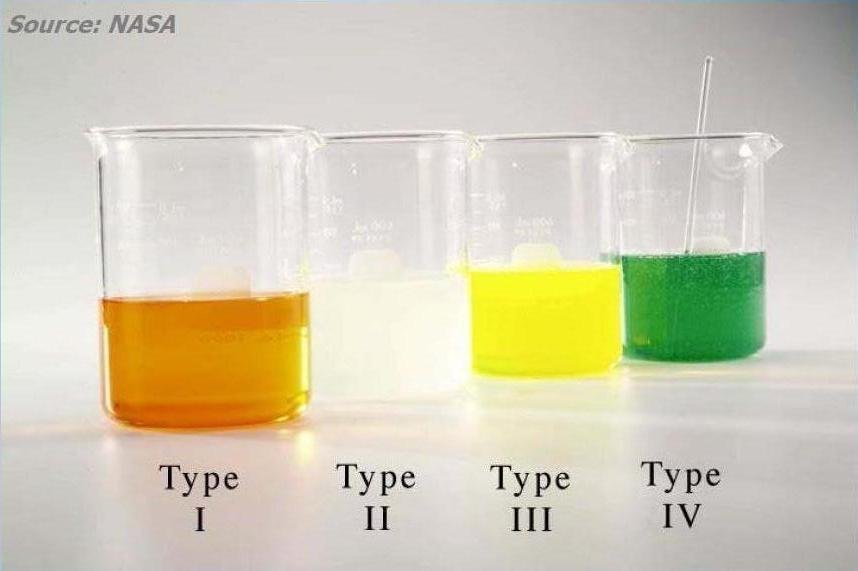

In 2019, two types of fluid were used at our airport — Defrost Eko-4 and Defrost EG-51, I think. Now we do not work with the latter (in the case materials, type 1 fluid is listed as Defrost EG-88.1 — Ed.). Containers with liquid were stored in a special airport warehouse. They were kept in different places and labeled as type 1 and type 4. The containers were translucent, so the contents could be seen. Type 1 liquid was pinkish-red, and type 4 was bright green, so our employees could not confuse them. In addition, in the cradle of the special vehicle there is a switch indicating the type of liquid. If the plane needed type 1 liquid, the switch was set to type 1. If type 4 was needed, it was set to type 4,said Shulyak.

According to the witness, there was another factor that ruled out error in using the liquid:

Type 4 liquid does not mix and does not heat up. It is used as is. But type 1 liquid is heated to almost 100 degrees. As soon as the technician turns on the gun to spray it, strong steam comes out. It is impossible not to notice it.

Lawyers for the deceased pilots and for injured passengers questioned the engineer about the process of diluting concentrated type 1 liquid with water and the stages of filling the special vehicle.

They wanted to ensure that airport staff had not violated procedures for preparing and applying de-icing liquid.

Each special vehicle is filled as the liquid in the tank runs out. It drives to the filling station on the airport grounds, and there a forklift fills the liquid from cubic barrels. Then it goes to another point, where type 1 liquid is automatically mixed with water in a ratio of 70 to 30 percent. People are not directly involved in this process, it is done entirely by the vehicle itself.

The engineer said it takes 10 to 25 minutes to fill one vehicle.

The volume of liquid used depends on weather conditions:

The tank of the vehicle holds 6 tons 800 liters. If there is heavy snowfall or the plane has been under snow for a long time, then two vehicles may be needed for de-icing. If the plane has just arrived and is flying back, and it is snowing, then only 500 liters may be needed. I will note that after de-icer No. 71 treated the Bek Air plane, it treated another plane as well. I do not remember the airline’s name now, unfortunately, but this same vehicle serviced that aircraft too.

According to Shulyak, he had four certified technicians working under him who independently supervised the process of refueling the special vehicles.

They recorded in a special log the date, time, volume, and type of liquid consumed, the remaining volume of type 1 liquid at the time of refueling, the volume of water used for dilution, as well as the number of the special vehicle, and they wrote their surname in the “performer” column.

The lawyer for the pilots asked the witness whether his subordinates had permission to carry out de-icing treatment of aircraft. Since the airport is a strategic facility, he argued, all employees must have certificates.

Shulyak replied:

Nowhere is it stated that the person filling the special vehicle-deicer has a certificate for admission to such work.

The defense attorney also asked about the night lighting at the airport filling station and the security of the special warehouse where the containers with de-icing liquid were stored. Shulyak replied that there are floodlights at the filling station that are switched on at night.

Therefore, the driver and operator of the special vehicle can clearly see what is being poured into the tank.

As for the warehouse, he said there is no separate security, since the entire airport is controlled by the security service. The warehouse for storing the liquid is located next to the fuel and lubricants warehouse, so the risk of sabotage at these facilities is minimized.

An outsider cannot penetrate the special warehouse to surreptitiously replace the containers with liquid or mix type 1 in the wrong proportion with water, Shulyak said.

One of the key issues that concerned both the defense and the prosecution was the quality control of the de-icing liquid.

The parties asked the witness who checked the contents of the containers when they arrived at the airport and how this was done.

Liquid was sampled for the so-called incoming analysis once a month. The airport laboratory staff took liter bottles from new packaging, washed and dried them, and then gave them to us. We poured the incoming liquid into them and returned them. They checked its composition. Without their conclusion, the liquid was not poured into the special vehicles.

The state prosecutor asked the engineer why de-icing liquid type 1 was used in a ratio of 70/30 and where the two special vehicles, No. 71 and No. 75, were stored in 2019.

The witness asked that these questions be forwarded to his superiors.

In 2019, the management of Almaty airport ordered the use of type 1 liquid in a ratio of 70/30 with water. We did it that way, and in 2025 the proportions were already 50/50. I don’t know what this is connected with. It’s better to ask our management. Four years ago, I stopped working with liquids, so I don’t remember the details now. But I confirm the testimony I gave earlier. I gave it voluntarily. As for special vehicle No. 71, it is still used at the airport. Previously, it was parked under a canopy in a special parking lot. Then the parking lot was demolished, and since then it has been stored in the open air with other vehicles.

Formulas

The second witness to testify was Timur Seilov. He currently works as an engineer at Scat Airlines, and in 2019, he worked at the airport in the repair and maintenance section of special vehicles as an engineer.

Seilov confirmed much of what his colleague Shulyak said.

There are four types of de-icing fluid in the world. Our airport used two of them — type 1 and type 4. The fact that the maximum possible concentration of type 1 liquid was used is due to the sharply continental climate of Almaty. During the day, we can have positive temperatures, and at night, negative temperatures. The decision to use a ratio of 70 to 30% was made in the 2010s. Then this ratio changed.

According to the witness, de-icing liquid was delivered to Almaty by rail from Russia. Employees of one of the airport departments checked the cube tanks for damage and the integrity of the seals, and for compliance of their labeling with what was indicated in the manufacturer’s passport.

The quality of the liquid had to comply with the technical specifications and international SAE standards. Therefore, the employees of the airport laboratory carried out incoming quality control. They removed the seal and examined samples of the liquid, only after that were the cube tanks sent for storage to a special warehouse. There they were stored at a certain temperature. The heads of the service, the duty shift, and the section, myself, and the aircraft technicians who worked in shifts had access to the special warehouse, Seilov said.

The lawyers asked whether the water meter had been checked since it was by this that the exact amount of water used to dilute type 1 liquid could be determined.

At that time, we had a new water meter. Usually the first check is carried out after five years, the subsequent ones every three years.

When the witness began to explain the technology of mixing type 1 de-icing liquid and heating it, the lawyers drew the court’s attention to a difference with what his colleague had said earlier.

Seilov said that the liquid was heated within the range of 60 to 82 degrees Celsius, while Shulyak had said the temperature was 100 degrees. Seilov also said that 1,000 liters of concentrated liquid were diluted with 430 liters of water, while Shulyak had said 300 liters of water.

We derived the ratio of liquid to water ourselves using a mathematical formula. We found a hint in the manufacturer’s table, where they even indicated the refractive index of light. To check the correctness of the ratio, we used a special device — a hand refractometer. The data was recorded in a log.

According to Seilov, all responsibility for the pre-flight preparation of the aircraft lies with the aircraft commander. He decides whether or not to treat the aircraft with de-icing fluid and whether to carry out a two-stage or single-stage treatment.

When the witness said that it was Commander Marat Muratbayev who gave the order to carry out a single-stage treatment of the stabilizer, the lawyer of the pilot asked Seilov how he could claim such a thing, since he was not in direct contact with the crew commander at the time of the de-icing treatment.

We do not have any contact with the crew. The order indicated the treatment of only the stabilizer of the aircraft, and there was the signature of the commander.

Strict Quality Control

According to the case materials, special de-icing vehicle No. 71 treated the wings, stabilizer, and elevator of aircraft of five other airlines on December 27, 2019. The Bek Air pilots ordered only the stabilizer treatment, and they ordered 153 liters of liquid instead of the standard 45.

Why they did this is being clarified during the trial.

The court then heard the testimony of other witnesses. One of them was Mereke Gubashev. In 2019, he served as a senior technician at the Burunday airbase of the National Security Committee. He was responsible for the pre-flight preparation of military aircraft An-26 and An-2, Yak-40 and Yak-42.

On the day of the tragedy, Gubashev was at Almaty airport, preparing an An-26 for takeoff. He checked the condition of the aircraft’s electrical system and fuel system, as well as the lighting in the cabin.

De-icing the aircraft is expensive, so we clear accessible areas of ice and snow ourselves so as not to pay extra money to the airport. We start with the nose of the aircraft, then move on to the wings and tail fin. We clean with homemade products and brooms, pour hot water on the hull. All this happens before the arrival of a special vehicle and full de-icing treatment, said Gubashev.

According to the military technician, he and his colleagues even clear the aircraft parking lot of snow — that is how strict the KNB aviation service’s requirements are for pre-flight preparation.

If it is necessary to remove snow and ice from a certain part of the aircraft, the commander orders anti-icing treatment. We, military technicians, call the airport dispatcher and name the required type of liquid, and he sends a special vehicle to us. While the operator of the special vehicle treats the fuselage, we observe its work from the ground.

From Gubashev’s testimony, it turned out that the KNB military aircraft mainly undergo a two-stage de-icing treatment. The results are determined both visually and tactilely, since icing often occurs in hard-to-reach places and cannot be identified by sight alone.

De-icing treatment of a military aircraft is carried out only after the crew and passengers have taken their seats. After it is completed, the captain comes out and carefully inspects the aircraft. If he is not satisfied with something, he extends the pre-flight preparation. In this case, we touch everything with our hands to assess the condition of the aircraft. If we need to see if there is ice on the wings, we use a regular stepladder. This is an additional service provided by the airport.

The Pilots

Having learned how pre-flight preparation of military aircraft is carried out in winter, the court was interested in how it is carried out during the same period in civil airlines.

The witness was Alexander Tsoi, commander of a Bombardier Challenger business jet. He told how his aircraft underwent de-icing treatment on December 26, 2019:

Our aircraft arrived in Almaty on December 17 and was parked until the 26th. According to the maintenance regulations, if the aircraft is in temporary storage, it is inspected every seven days. Our aircraft was inspected on December 24, and the technical staff suggested treating it with de-icing liquid type 1. I agreed. I would like to note that the technical staff only suggests carrying out de-icing treatment in a certain volume and with a certain type of liquid, and the final decision is made by the aircraft commander.

According to the witness, the commander makes a decision depending on the weather conditions.

Sometimes the plane is treated with two types of liquid:

Almaty is located in a lowland, so you need to be prepared for fog to descend. And this is already a prerequisite for the formation of icing on the wings and stabilizer. In general, special attention should be paid to the wings, since the flaps and spoilers (aerodynamic controls of the aircraft — Ed.) are located there. If the plane has been standing in the open air for more than six hours, the engineering and technical staff must also check the equipment, since this is enough time for the plane to become covered in snow and ice.

According to the witness, his plane was next to a Fokker 100, so he saw how the neighboring crew was undergoing pre-flight preparation.

But he spoke about this somewhat incoherently, since he was constantly distracted by clarifying questions from lawyers.

I saw that the plane was not clean… During the de-icing treatment, the technician was near the nose. He communicated with the crew using gestures… Special vehicle No. 71 was pouring in the liquid, located at one point, there was no one nearby.

From the very beginning of the trial, the lawyers have drawn the court’s attention to the orders for the use of de-icing liquid. One of the documents was corrected by hand, so the defense is trying to find out how and why this happened.

Witness Tsoi briefly explained the procedure for filling out the form:

The order for the use of liquid is written out in one copy. This is a kind of original. Then it is copied and given to other parties — the customer, the accounting department. Corrections to the order are possible, but they are entered into this primary source, the original, and then copies are made from it. Thus, all parties have the same data on hand.

The representatives of the injured party asked the business jet commander how justified the actions of his colleagues, Muratbayev and Muldakulov when they decided to take off for the second time after the unsuccessful first attempt.

According to the prosecution, the pilots made mistakes during the takeoff of the Fokker 100.

We have paragraph 646 of the Flight Operations Rules, which discusses the actions of pilots during the takeoff of an aircraft. So, if during the takeoff the aircraft deviates from the course or there are other problems, then the commander aborts the takeoff. But at the time of the takeoff, the Fokker 100 had no deviations. The abnormal situation began after lifting off the runway, when the aircraft began to bank in different directions in the air. At the time of the takeoff, the commander should have stopped the flight, without waiting for the moment of the decision-making speed, when the flight cannot be stopped, no matter what happens. He could not control the aircraft, which did not want to gain altitude, Tsoi concluded.

Our journalists are following the progress of the court proceedings in this high-profile case.

Original Author: Zhanar Kusanova

Latest news

- The War in Iran Opens a Window of Opportunity for Kazakhstan’s Oil Sector, Analysts Say

- Iran Conflict Escalates Beyond the Gulf: What Kazakh Experts Say About Risks for Central Asia and Kazakhstan

- Kazakhstan Prepares Possible Evacuation of Its Citizens From Iran

- LRT in Astana Is Reaching the Finish Line: The Launch Is Expected in the Coming Months

- Kazakhstan Ready to Help the UAE Amid Escalation in the Region

- Tokayev Discusses Middle East Escalation With Qatar’s Emir

- Airlines Ready to Bring Kazakhstanis Home From the Middle East

- Tokayev Sends Support Messages to Gulf Leaders Amid Regional Escalation

- Kazakhstan Bans Its Airlines From Flying Over Several Middle East Countries

- Astana Strengthens Security Measures Amid Escalation Around Iran

- Tokayev Meets U.S. Ambassador Stufft, Discusses Board of Peace Cooperation

- Mangystau Launches AI-Assisted School Monitoring to Prevent Teen Suicidal Behavior

- Kazakhstan to Supply UK With Critical Minerals

- AI Faculties for Educators to Open in Kazakhstan: What Other Changes Are Coming to the Education Sector

- There Are Medals — But Not Enough Ice: What’s Happening to Figure Skating in Kazakhstan

- Is Kazakhstan’s Nuclear Power Plant Project at Risk After New UK Sanctions? Rosatom Responds

- Prosecutor General’s Office Suspends Extradition of Navalny Ex-Staffer Detained in Almaty

- Former EBRD Executive Jürgen Rigterink Elected as New Independent Director on Bank RBK’s Board of Directors

- Kazakhstan Near Bottom of Retirement Comfort Ranking

- Kazakhstan to Open New International Flights Across Asia, the Middle East and Europe