Kulibayev's Company Helps Shymkent Refinery with Gasoline Production. Part 2

Since 2011, the plant has been engaged in the modernization of a diesel installation. The last part was a compressor station. Its real cost was higher than the amount in the estimate. The general contractor was the company DN System, the stakeholder (founder) of which was the business partner of Timur and Dinara Kulibayev. Orda looked into the situation.

In the last part, Orda wrote that the breakdown of the heat exchanger at the Shymkent refinery cannot be considered a force majeure. The part's malfunction was known at the beginning of the year. In March, the specialists of the manufacturer, which is located in China, even came to fix it. They reported that under favorable conditions, the heat exchanger will be able to work for no more than a year. It, however, began to fail again in May.

Again?

On July 18, Astana hosted a press conference with Deputy Chairman of KazMunayGas Dmitry Makeev. He said that the Shymkent refinery had completed the repair of the heat exchanger. The installation has been launched, the technological parameters are being stabilized, and the plant is starting normal operation.

On July 22, Vice Minister of Energy Yerlan Akkenzhenov visited the Shymkent refinery. He got acquainted with the work of the facility and held a meeting. But the moment regarding the connection of the plate heat exchanger on the catalytic reforming unit of gasoline in the press release is what interested an Orda correspondent. The very ill-fated T-251 that failed back in June.

"According to the management of the plant, the operations for connecting the plate heat exchanger in operation will be completed on July 23, with subsequent output to normal technological mode on July 24,"

the press service of the Ministry of Energy reported.

In other words, somewhere between July 18 and 22, did the heat exchanger fail again? Why connect it twice? Most likely, the fault is the hot weather in the south of Kazakhstan. According to another version, Dmitry Makeev was misinformed, otherwise, why would he deceive the general public?

12 Years

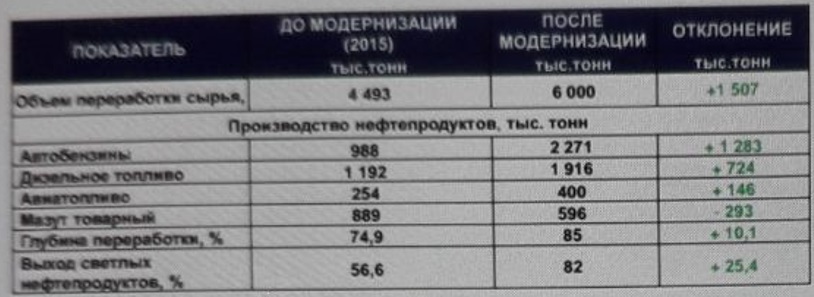

In 2011, the Shymkent refinery started the modernization of a diesel plant to produce fuel of environmental standards K4 and K5. It was planned to bring diesel production to 2 million tons per year. However, the installation has been repaired three times in 12 years.

In September 2015, KazMunayGas announced that the system had been modernized. A hydrotreating plant was put into operation, providing a certain quality. The refinery used the developments of Axens (France) and Sud Chemie (Germany). This was the first step in the SNPZ's modernization project. From that moment, they began to produce ecological diesel fuel of environmental standards K4 and K5. This is an analogue of the European standards Euro-4 and Euro-5, adopted in the countries of the Customs Union.

Officially, no one talked about diesel fuel prices, but in early September 2015, an order was issued by the Minister of Energy. According to it, prices for summer and off-season diesel fuel should not exceed 99 tenge per liter. A lot has changed since then, the price tag at refuelling stations for diesel fuel is around 295 tenge.

On December 15, 2017, PKOP LLP suddenly announced that it had switched to the production of diesel fuel of ecological class K4 and K5 according to the requirements of the Customs Union's technical regulations. This was previously stated by KazMunayGas and Samruk-Kazyna. Why the same thing was reported twice, even with a difference of two years, is unclear. Perhaps the owners of the Shymkent refinery simply forgot that they have been producing this diesel.

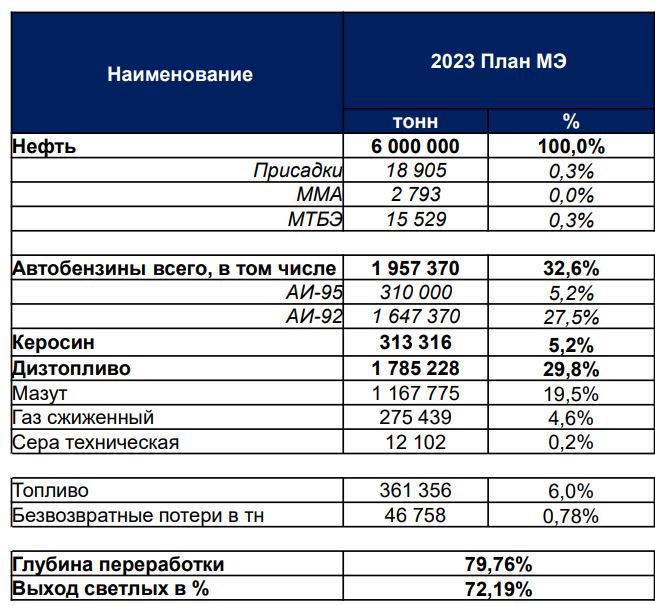

$2 billion has been allocated for the modernization of the refinery, but the facility has not reached its target. It was supposed to produce 2 million tons of diesel fuel per year. As a result, Kazakhstan received only 1.6 million tons. Why didn't it work out? No one answered this question. There is no magic figure to this day. Last year, Qasym-Jomart Toqayev was informed about 1.9 million tons of diesel.

Expectation VS Reality: How The Real Amounts Turned Out to Be Higher than in The Estimates

As GlobalNews wrote, the modernization of the diesel plant was supplemented with a compressor station the last time. Approximately 27-29 million US dollars were spent on it despite the fact that a similar installation at the Atyrau refinery cost almost 2 times cheaper: $15-16 million.

At the same time, the cost of the compressor station itself in the design and estimate documentation was 7.7 billion tenge (December 2020 at the rate of 430 tenge per dollar - 18 million dollars). But already in finalized documents, the same detail cost 12.6 billion tenge. According to colleagues, the LLP did not provide any justification for such a sharp increase in the cost.

They also decided to include the unfinished construction in the "operating expenses". This can be seen as a violation, as, theoretically, all unfinished objects are listed as construction in progress. After commissioning, all parts are accepted by one act to the balance of the plant at actual costs.

"Now there are high risks that there is a procedure going on at the PCOP on how to legitimize the "overspending". And, perhaps, there is even a "definite" solution so that part of the contract costs are reflected in operating expenses – work with DED (design and estimate documentation- Ed.), dismantling, transfer of existing refrigerators, modernization of columns, replacement of pipelines and re-binding, strengthening of overpasses, equipment for substation and fire protection. They must be in the acts on construction and installation works (CIW)",

a source at the refinery shared.

"Since 2011, the diesel plant has been undergoing modernization. They ordered five DEDs with the involvement of general contractors, trying to bring diesel production to 2 million tons per year. As a result, we spent about $40 million on this. The last attempt was the purchase and construction of a compressor room. Mechanical completion — in March-April 2022. The general contractor contract was signed in August-September 2020. Most likely, this was done without the presence of a DED because the conclusion of the state expert examination was received much later – on December 31, 2022. Plus commissioning. GASK strongly objected to the final acceptance of the act because the final cost of the object with delivery was much higher than the estimates in the DED,"

the source at the Shymkent refinery told Orda.

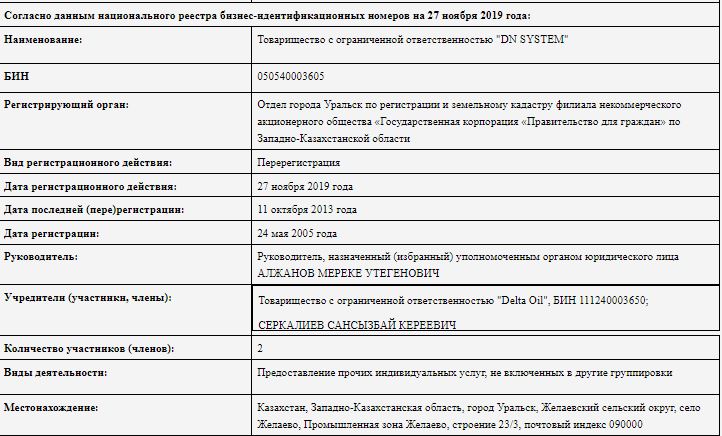

The general contractor was the company DN System. The contract was concluded for the CIW and the purchase of equipment with the payment of an advance under a letter of guarantee. For some reason, the company did not provide a bank guarantee. As the source told Orda, the LLP has not completed the commissioning work.

"Auditors from KazMunayGas recommended fining enterprises up to 400 million tenge. But the management of "PKOP" did not allow this to be done. Moreover, Technical Director Bakhyt Yeregenov signed the acts of commissioning, in which DN System did not participate. In general, it is not the first time that Yeregenov has signed a contract with a general contractor before receiving a state examination. Is that right? PKOP LLP, not yet knowing the exact estimated cost of the project, violated the law on architectural urban planning and construction activities,"

the source added.

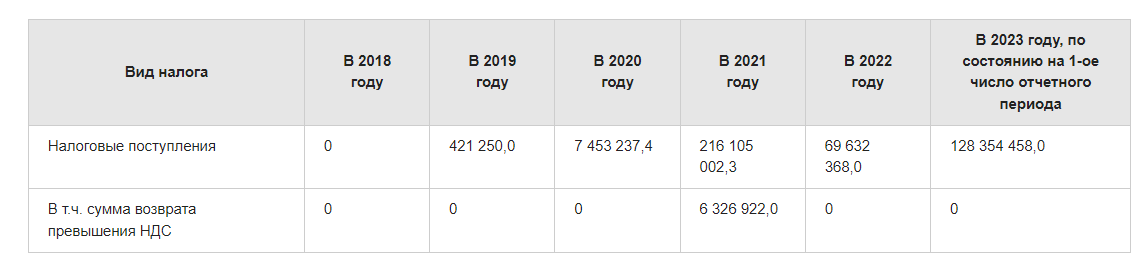

DN System LLP was created back in 2005. The company is registered in Uralsk, in the industrial zone of Zhelaevo 23/3. The director is Mereke Alzhanov, and the founder is Sansyzbai Serkaliyev. In 2021, the company paid 216 million tenge in taxes to the treasury.

The company is engaged in the construction of non-residential buildings. A seemingly ordinary-looking company, but there is one peculiarity

At a certain period, the founder of DN System was a company associated with Timur and Dinara Kulibayev

Shymkent Refinery's Connection to The Former President's Daughter and Son-in-law

Among the stakeholders (founders) of the DN System company in the period from November 27, 2019, to June 7, 2020, the co-founder was Delta Oil LLP along with Sansyzbai Serkaliyev. The legal entity was later replaced by Aspandiyar Yelibayev, director of Delta Oil. In November 2022, only Serkaliyev remained on the list of owners.

June 8, 2020

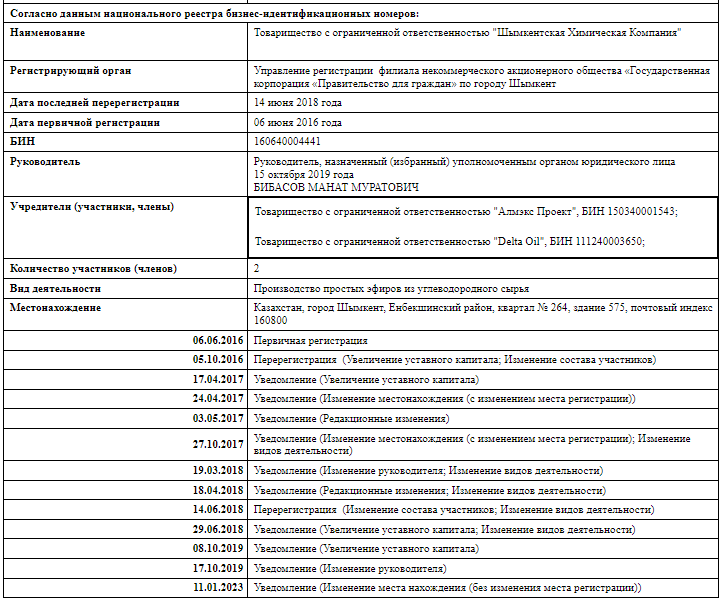

According to data for April 2023, Delta Oil and Aspandiyar Yelibayev are included in the list of affiliated entities of JSC "Subsidiary of Halyk Finance of the People's Bank of Kazakhstan". The company is a co-founder of the Shymkent Petrochemical Company (SHKK LLP). The second founder is Almex Project LLP. Dinara and Timur Kulibayev own it.

One Pipeline Overpass for Two

In September 2021, a plant for the production of methyl tert-butyl ether (MTBE) was opened in Shymkent. The construction of the facility and the purchase of equipment were carried out, including with the money of the Development Bank of Kazakhstan. The financial institution has allocated 9 billion tenge for up to 10 years within the framework of the state program of industrial and innovative development of Kazakhstan. The total cost of the project amounted to 13.7 billion tenge. The remaining part came at their own expense. It was not reported how much of the 4.7 billion the Kulibayev family invested.

The plant's production capacity is 57 thousand tons of MTBE per year, which allows it to fully cover the needs of the domestic market. This is one of the important oxygen-containing high-octane components that are used in the production of gasoline. It is MTBE that helps to get the same AI-95 gasoline.

But how are the Shymkent Refinery and the Shymkent Chemical Plant connected? Directly. A pipeline overpass is installed between the objects. The chemical plant receives both raw materials from the SNPZ via it and energy resources in the form of steam and purified water.

What is the raw material? During oil refining, gas is formed. Isobutylene is extracted from it, which is necessary for the production of an additive to motor fuel. The remaining gas is returned to the main production. At the main plant, isobutylene reacts with methanol, resulting in the production of ether.

Could the connection of DN System LLP with the Kulibaevs and the Shymkent Petrochemical Company become some kind of protection against a fine of 400 million tenge, which the auditors of KazMunayGas have proposed to impose? This question remains unanswered.

In the next part, the editorial board of Orda will talk about personnel problems and a defect in catalytic cracking.

Original Author: Maria Gorbokonenko

DISCLAIMER: This is a translated piece. The text has been modified, the content is the same. Please refer to the original piece in Russian for accuracy.

Latest news

- Scammers Posing as Security Agents Trick Architect Into Selling Property

- Ulytau Officials Respond to Fine: Blogger Was Penalized Over Unfounded Corruption Claims

- Kazakhstan Lifts Gallium Export Duty

- Chinese Firm Proposes to Fund New Port and Logistics Hub in Mangystau Region

- ForteBank Stock Soars on Home Credit Deal, Then Plunges 30% in a Day

- Coins Believed to Be Tied to Kairat Satybaldyulyuly to Be Auctioned

- Ukraine’s Military Intelligence Chief Says Ceasefire Should Come Before Year’s End

- Kyrgyz Citizen Fined in Kazakhstan for Carrying Banned Book Across Border

- Trial of Former Financial Police Officers in Khorgos Case No. 1 Closed to Public Over State Secrets

- Kazakhstan to Ban Outdoor Currency Rate Displays at Exchange Offices Starting September

- Armenian Court Orders One-Month Detention for Tashir Pizza Executive Amid Ongoing Investigation

- Kazakhstan May Require Banks to Offer Deferrals to Socially Vulnerable Borrowers

- Almaty Utility Pursues Debt Collection for Unpaid Heating and Hot Water Bills

- Kazakhstan and Afghanistan Sign Railway Memorandum

- Kazakhstan's National Bank Keeps Interest Rate at 16.5%, No Cuts Expected Until 2026

- Vyacheslav Kim Finalizes Purchase of Alatau City Bank

- Wild Arman Associate Detained in UAE Over Alleged Role in Qantar Riots

- Ulytau Region Akim Sues Woman for 495,000 Tenge Over TikTok Video

- Ukrainian Entrepreneurs Move to Buy BTA Bank from Kazakh Businessman Kenes Rakishev

- Kazakhstan’s Foreign Debt Hits 170.5 Billion USD in Q1 2025