How Much Does Gas from Karachaganak Actually Cost?

Crude gas from the Kazakhstan field is sent to the Orenburg Gas Processing Plant, where it is processed and then exported. KazMunayGas receives billions in dividends for this, but what does Kazakhstan get? Orda.kz looked into the details of Karachaganak’s history.

Kazakhstan signed production-sharing agreements (PSAs) or production-sharing contracts (PSCs) with large multinational energy consortia in the early years of independence. There are three such contracts in Kazakhstan: Kashagan, Dunga and Karachaganak. All oil produced under such contracts is divided into Cost oil (compensatory oil and gas raw materials) and Profit oil (profitable oil and gas raw materials). The latter is also distributed between parties in specific proportions. The sale of Profit oil generates income for Kazakhstan.

Orda wrote about how KazMunayGas received 10% in the project in the first part about Karachaganak. The country thereby began to receive money from the field within the framework of Cost oil and Profit oil.

In 2014, the Italian company Eni miscalculated the extracted raw materials. As a result, Kazakhstan lost about $2 billion. To rectify the situation, a second agreement was signed in October 2018. As part of the third agreement, the Karachaganak Project alliance financed the gasification of Astana.

CPC Woes

Gas condensate, and in fact light oil, is exported from the Karachaganak field via the Caspian Pipeline Consortium (CPC). In many ways, the pipeline allows Western companies to save on oil transportation costs. CPC revenue reimburses logistics costs. This dramatically increases margins for global giants such as Chevron, Exxon Mobil and Shell.

The matter of sanctions arose after the onset of the war in Ukraine. In March 2022, the Washington bureau chief of the Financial Times, James Politi, said that sanctions against Russian oil would not apply to the CPC. Peculiar circumstances, however, started to unfold.

On March 22-23, 2022, the power frame had shifted on one of the floating hoses of the remote mooring device (VPU). And the hose of the inner sleeve of the VPU-2 was damaged. It was impossible for the equipment to operate. Some VPUs were temporarily suspended for washing and repair. A strong storm at the port of shipment in Novorossiysk caused this. The pipeline was only working at 60%. Chairman of the CPC-R Board of Directors Daniyar Berlibayev assured that "there was no political context." Kazakhstan had to reduce its oil production plan from 87.5 million to 86 million tons.

It was promised that repairs would begin on April 15. Damage to Kazakhstan was estimated at 220-230 million dollars by this time. On April 20, 2022, it was announced that the replacement of pipes with CPC was completed. A month after the breakdown, on April 24, the pipeline began operating at almost full capacity. On April 23, VPU-3 was put into operation at the marine terminal after repairs, and VPU-1 was functioning as per usual. VPU-2 was temporarily not operating.

A new turn of events occurred three days later. Because of an oil spill, the arbitration court of the Krasnodar Territory demanded 5.3 billion rubles from the CPC marine terminal. This happened on August 7, 2021, during the loading of the ship "Minerva Symphony". The consortium did not agree with the calculation. The court's decision remained the same regardless.

From June 15 to June 25, 2022, the Caspian Pipeline Consortium announced that oil will be shipped only from one of the three outrigger berths. The reason was a planned survey of the water area of the Ministry of Emergency Situations of the Russian Federation. The shippers received promises that their requests would be fulfilled. But on June 19, Russia temporarily reduced the shipment of Kazakhstani oil due to 50 mines from the Second World War. Kazakhstan has stated that we did not incur losses due to mine clearance. The Ministry of Energy then reported that the CPC would resume work in full on June 25.

And in July 2022, the pipeline "tripped up" once more. This time the Novorossiysk District Court suspended its activity for 30 days. The reason was an environmental violation at production facilities. It was identified during an inspection in May, but only a month later a protocol was drawn up. The consortium promised to appeal this decision and succeeded. A fine of 200 thousand rubles was issued in lieu of another halting of operations.

On August 17, 2022, deja vu struck the CPC. There was a storm in the Black Sea. Two of the three VPUs were suspended to check the system. This did not significantly affect oil supplies, as Kazakhstan’s two large oil fields, Tengiz and Kashagan, were undergoing repairs. A few days later it became known that VPU-1 and VPU-2 would suspend work due to cracks. Deputy Chairman of the Board of KazMunayGas for Economics and Finance, Dauren Karabayev, said at the time that the ongoing repair work at CPC does not affect the shipment and transportation of Kazakhstan’s oil. The remaining VPU worked without violating the delivery schedule.

On October 21, Energy Minister Bolat Akchulakov promised that the berths would resume operations after October 25. The consortium, howe was not as confident. Shipments were carried out only from VPU-3, while the other two berths were under repair. But the weather quickly improved. On October 31, the CPC press service published photos of the replacement of the buoyancy tank.

On November 12, CPC announced the completion of repairs at VPU-1 and its full restoration. They were only planning to replace VPU-2’s buoyancy tank.

In February 2023, the CPC stopped the shipment of oil through Novorossiysk due to a strong storm on the Black Sea. After a few days, normalcy returned.

Karachaganak Expansion: A New Project

In November 2022, a final decision was made to expand Karachaganak. The volume of investments should amount to $700 million. The construction of the processing complex-1B should start in 2023. The project includes the construction of a sixth gas re-injection compressor, the installation of gas drying, and the expansion of the collection system and related facilities.

The goal is to extend the "shelf of production" (Constant level of mineral extraction – Ed.) of liquid hydrocarbons in Karachaganak. Both Kazakhstan and members of the alliance will receive dividends from the implementation of the project.

PRK-1B is a continuation of major projects at the Karachaganak field. In 2019, Karachaganak Petroleum Operating B.V. announced the commissioning of the 5th in-field pipeline. And in 2021, the project of lifting production restrictions on gas was completed. The 4th gas compressor was built in 2022. Also at the implementation stage is PRK-1A.

Profit or Loss?

Crude gas from the Karachaganak field is sent to the Orenburg Gas Processing Plant. Some of the finished products are returned to the domestic market and some are sold further down the chain. In June 2022, it became clear that the volume of gas processing will increase to 11 billion cubic meters per year. 1.7 billion cubic meters per year will enter our market.

A company was needed to supply gas to the GPP. To this end, Kazakhstan and Russia signed an international agreement "On cooperation in the gas sector" on November 28, 2001, and established KazRosGaz LLP. Half of the authorized capital belongs to KazMunayGas. The other half belongs to Gazprom PJSC. On June 17, 2015, KazMunayGas transferred its share to the trust management of KazTransGas.

KazRosGaz is engaged in the purchase and sale of gas from the Karachaganak and Tengiz fields. Gas is mainly transported to the Russian border and then sold on the markets of foreign countries.

According to the terms of the contract between Kazakhstan and Russia signed in 2021, when selling processed Karachaganak gas for export, the price of 1000 cubic meters of gas of Russian origin for us will be 4,206 rubles. In total, up to 2 billion cubic meters of gas are supplied to the domestic market per year. These are so-called counter deliveries. That is, KazRosGaz LLP takes crude gas from the Karachaganak field, processes it at the Orenburg Gas Processing Plant and then sells it to Kazakhstan. The price per thousand cubic meters of gas is much higher in the countries of Europe and the CIS.

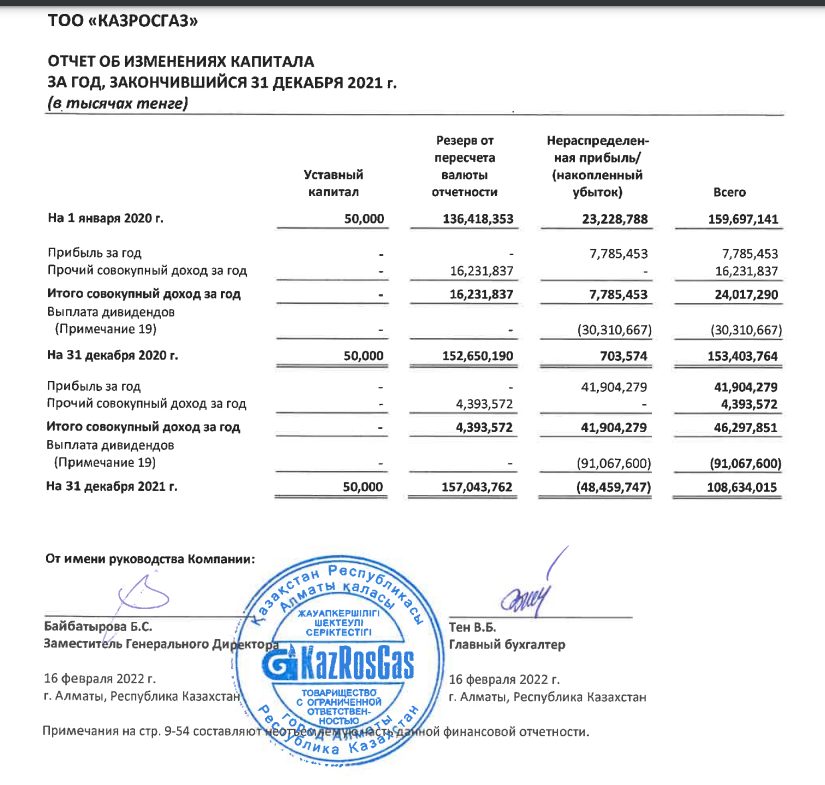

According to the financial report of KazRosGas LLP for 2021, the company paid dividends of 91 billion KZT ($211 million). In other words, each of the owners of the enterprise received 45.5 billion KZT. The authorized capital of the organization is 50 million KZT.

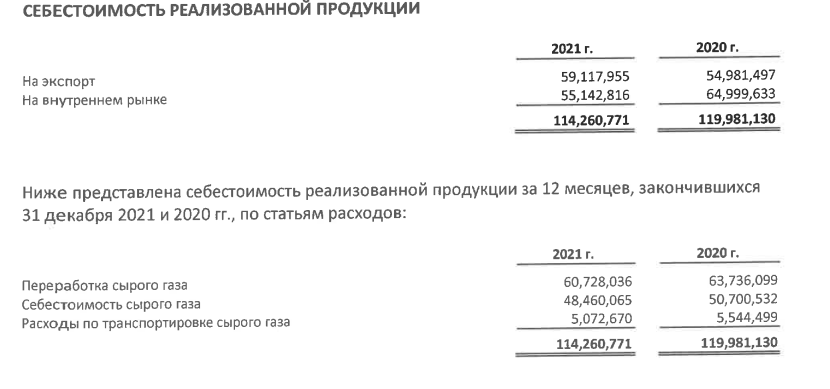

Sales of dry gas brought 119 billion KZT to the LLP in 2021. And the costs of processing, cost and transportation of crude gas amounted to 114 billion KZT. According to the financial report, about 42% and 18% were received from the sale of dry gas from KazMunayGas and Gazprom Schweiz AG.

In 2021, the company used the exchange rate of the dollar to tenge at the level of 431.8 KZT. The weighted average exchange rate was 426.06 KZT. Due to the exchange rate difference, the net loss in 2021 amounted to 3.1 billion KZT. This is mainly due to accounts receivable and VAT recoverable, which are calculated in KZT. The dollar remains the functional currency.

The company, in addition to the exchange rate loss, has administrative expenses as well as transportation and sales. The LLP spends up to 24 billion KZT for these needs in total.

But soon the situation will change. Karachaganak will have its own gas processing plant.

New GPP in Karachaganak

In March 2022, it became known that representatives of the alliance plan to expand the project. They decided to build a GPP with a capacity of up to 4 billion cubic meters of gas and 600 thousand tons of LPG (propane-butane) per year to achieve this. The construction of the new plant was estimated at 3-3.5 billion dollars. The Ministry of Energy, together with the alliance, has begun to develop a feasibility study.

One of the reasons for the new project was an unscheduled repair at the Orenburg Gas Processing Plant, which began in November 2022. Something needed to be repaired at the sulfur production and exhaust gas purification plant and gas purification and drying plants. As a result, the Russian company reduced the processing of Karachaganak gas by 40%. This caused the extraction of natural resources to decrease.

What will happen to KazRosGaz LLP after the commissioning of the new plant? What volumes of gas will be supplied to the Orenburg Gas Processing Plant? And also how does the Karachaganak Project alliance plan to transport the processed gas from the new plant further to Europe? There are no answers to these questions yet.

Original Author: Maria Gorbokonenko

DISCLAIMER: This is a translated piece. The text has been modified, the content is the same. Please refer to the original article in Russian for accuracy.

Latest news

- Kazakhstan Lifts Gallium Export Duty

- Chinese Firm Proposes to Fund New Port and Logistics Hub in Mangystau Region

- ForteBank Stock Soars on Home Credit Deal, Then Plunges 30% in a Day

- Coins Believed to Be Tied to Kairat Satybaldyulyuly to Be Auctioned

- Ukraine’s Military Intelligence Chief Says Ceasefire Should Come Before Year’s End

- Kyrgyz Citizen Fined in Kazakhstan for Carrying Banned Book Across Border

- Trial of Former Financial Police Officers in Khorgos Case No. 1 Closed to Public Over State Secrets

- Kazakhstan to Ban Outdoor Currency Rate Displays at Exchange Offices Starting September

- Armenian Court Orders One-Month Detention for Tashir Pizza Executive Amid Ongoing Investigation

- Kazakhstan May Require Banks to Offer Deferrals to Socially Vulnerable Borrowers

- Almaty Utility Pursues Debt Collection for Unpaid Heating and Hot Water Bills

- Kazakhstan and Afghanistan Sign Railway Memorandum

- Kazakhstan's National Bank Keeps Interest Rate at 16.5%, No Cuts Expected Until 2026

- Vyacheslav Kim Finalizes Purchase of Alatau City Bank

- Wild Arman Associate Detained in UAE Over Alleged Role in Qantar Riots

- Ulytau Region Akim Sues Woman for 495,000 Tenge Over TikTok Video

- Ukrainian Entrepreneurs Move to Buy BTA Bank from Kazakh Businessman Kenes Rakishev

- Kazakhstan’s Foreign Debt Hits 170.5 Billion USD in Q1 2025

- Regulator Flags Pricing Issues in Yandex Go Audit, Company Ordered to Adjust Policies

- Azattyq Prepares Lawsuit Against Kazakh Foreign Ministry Over Denied Press Accreditations